REVO AIR INTERCOOLER

1.8/2.0 TFSI

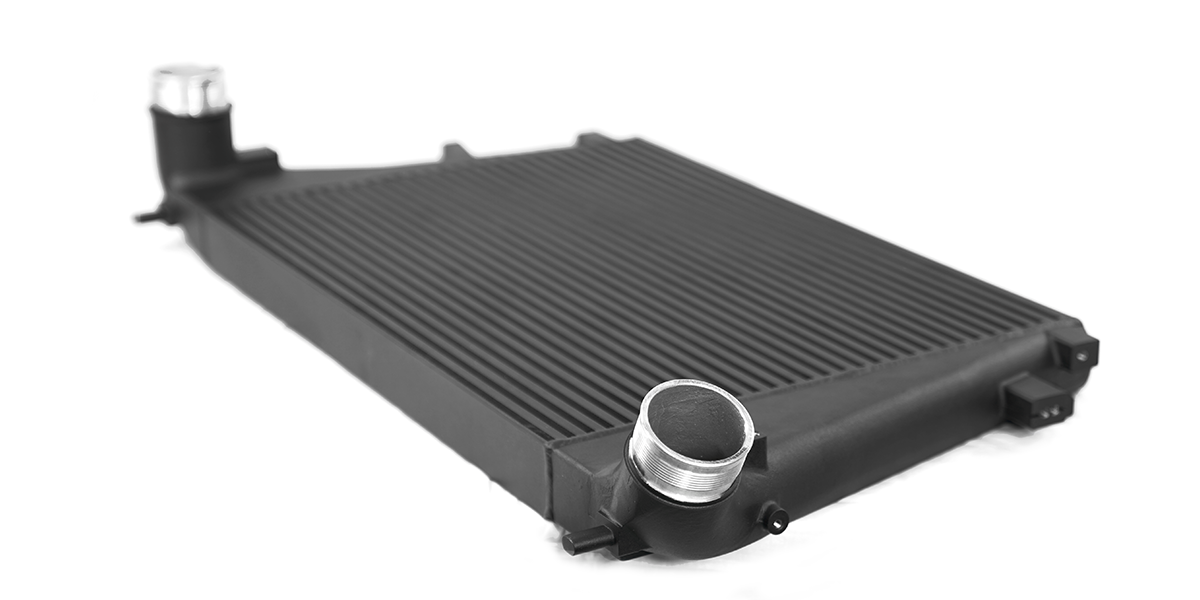

The Revo Intercooler utilises unique design features to lower intake air temperatures, minimise pressure drop and allow the engine to produce impressive power and torque with Revo Software. The unique end tank profile promotes internal laminar flow thus decreasing turbulence and increasing airspeed into the bespoke bar and plate core. These features enhance charge air cooling giving you access to more power throughout the rev range.

The limitations of the stock intercooler were apparent throughout testing. The stock part consistently struggled to manage charge air temperatures, even under normal driving conditions. The Revo Intercooler has been designed to improve on every restrictive element of the stock cooler, enhancing cooling efficiency by lowering intake air temperatures even compared to the Audi S3 (8P) cast aluminium intercooler, allowing you to drive harder, for longer.

KEY FEATURES

- Bar & Plate Core Design

- Fully Cast End Tanks

- OEM Fitment

- 51% Increased Core Volume over a standard cooler

- 21% Increased Core Volume over an OE S3 cooler

- Lower Intake Temperatures

INCREASED CORE VOLUME

The Revo Intercooler was built around a simple principle; create a cooler that can keep up with your demand for power. Designed from the ground up, the Revo Intercooler has a much larger core volume than the OEM part and offers perfect fitment, improving cooling by utilising the full volume of the stock location space as well as cold ambient air from the front of the vehicle.

END TANK DESIGN

End tanks play an important part in managing pressure drop and work in harmony with the core to promote airflow, the stock ones are inefficiently designed and create turbulent air in corners. These sections create a naturally small cross-sectional flow area, slowing charge air and increasing pressure drop. The Revo end tank geometry maintains the largest possible cross-sectional flow area to and from the core by removing these turbulent pocket areas found in the OE design. Coupled with a cast interior surface finish, the Revo end tanks allow air to flow freely without obstructions from turbulent air pockets found in the OE intercooler. End tanks play an important part in maintaining pressure and work in harmony with the core to promote airflow, the Revo end tanks are designed to offer the optimal balance between both of these key features.

BAR AND PLATE CORE

Designed with a bar and plate core to maximise the efficiency of heat transfer and minimise flow resistance, the Revo Intercooler easily outperforms similar tube and fin alternatives in both aspects. The Revo Intercooler goes a step farther: featuring carefully specified fin sizing and geometry to further optimise the balance between air cooling and flow restriction. The ambient core side utilises shorter fins with specially designed louvres to slow ambient air passing through the core, which improves heat transfer. While the charge core side features an offset internal fin design to balance surface area and air resistance to aid cooling ability and minimise pressure drop.

SILICONE HOSES

Supplied with stronger oil-resistant silicone hoses, the Revo Intercooler can be installed using the stock pipework or recommended Revo Intercooler pipework (Coming soon). The internal diameter of each silicone is precisely matched to the inner diameter of the ribbed intercooler inlet and outlet connections along with a unique Flush Fit design, allowing a smooth transition between components.

BRACKETS

To ensures precision fitment, Only Revo offers a CNC machined bracket system. Produced to a superior tolerance than that of a cast mounting system, this unique feature also ensures that the supporting brackets are strong and less prone to failure.

RESEARCH AND DEVELOPMENT

All Revo products are designed in-house using the latest 3D printing technology, CAD and CFD software. Every product is rigorously tested utilising an in-house dyno and Revo data acquisition software. The Revo intercooler minimises turbulence while maximising heat transfer, promoting cooler air temperatures and low-pressure drop. This helps retains power and torque throughout the rev range as highlighted during controlled Dyno testing.

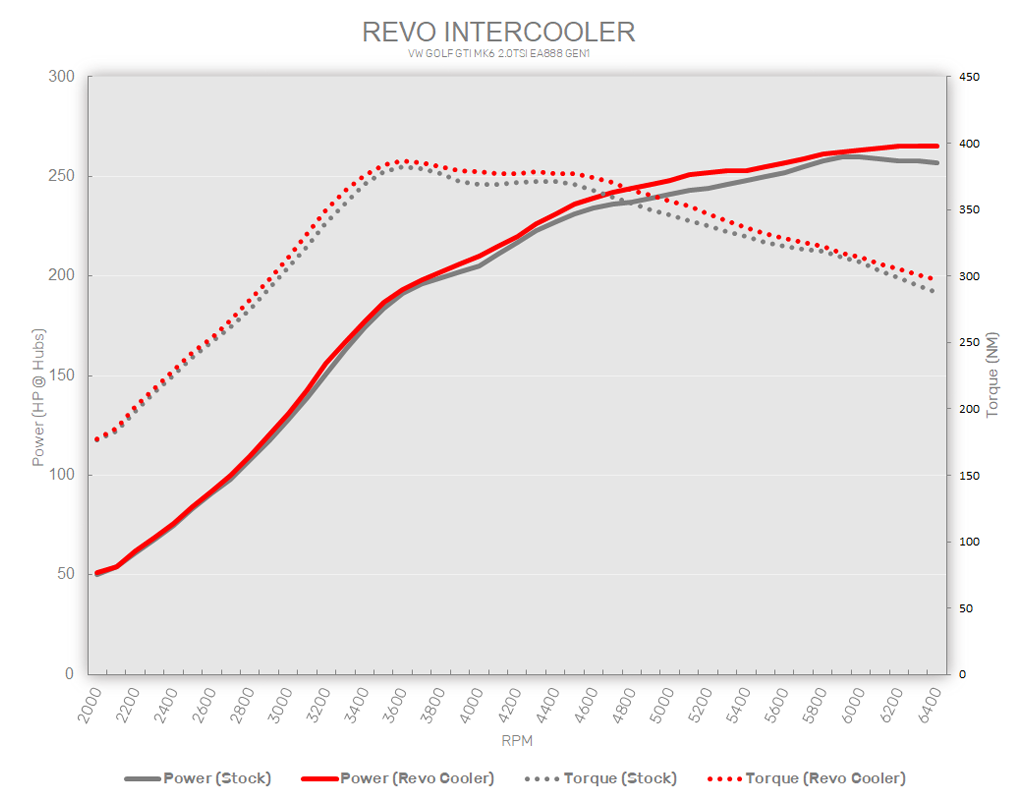

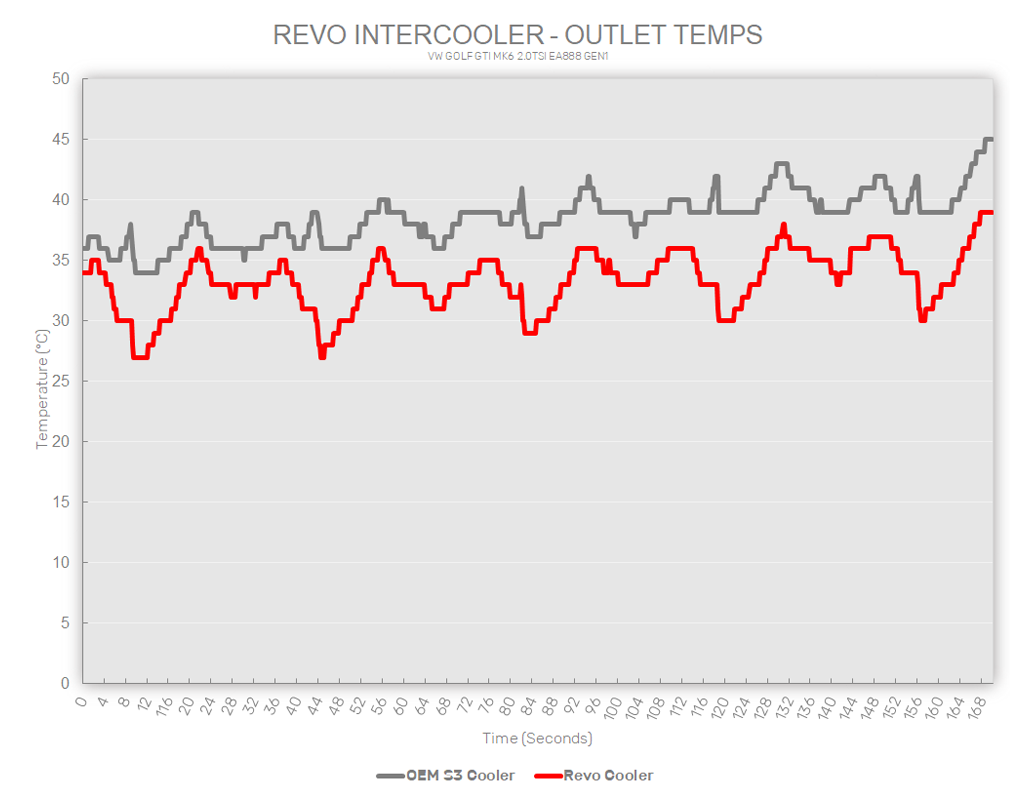

The Revo Intercooler was tested in-house to compare the performance against that of the stock Intercooler. First tested on a vehicle running the OE S3 (8P) intercooler with a Revo K04 Kit, Revo production KO4 software, a Revo air intake system and full Eurojet exhaust, the Revo Intercooler was then installed and tested in the same controlled environment to highlight the benefits of it’s enhanced cooling.

PERFORMANCE DATA

Golf GTI TSI EA888 Gen1 with Revo K04 upgrade, OE S3 (8P) intercooler and Revo open cone air intake system and full Eurojet exhaust.

Showing the last of five consecutive dyno runs, the efficiency of the Revo Intercooler over the OE S3 intercooler is highlighted. With max gains of +8 HP & +11NM Torque, along with increased performance throughout the entire rev range, the stock intercooler struggles to effectively function in comparison to the Revo Intercooler which remained consistent throughout, losing no peak power over the 5 runs.

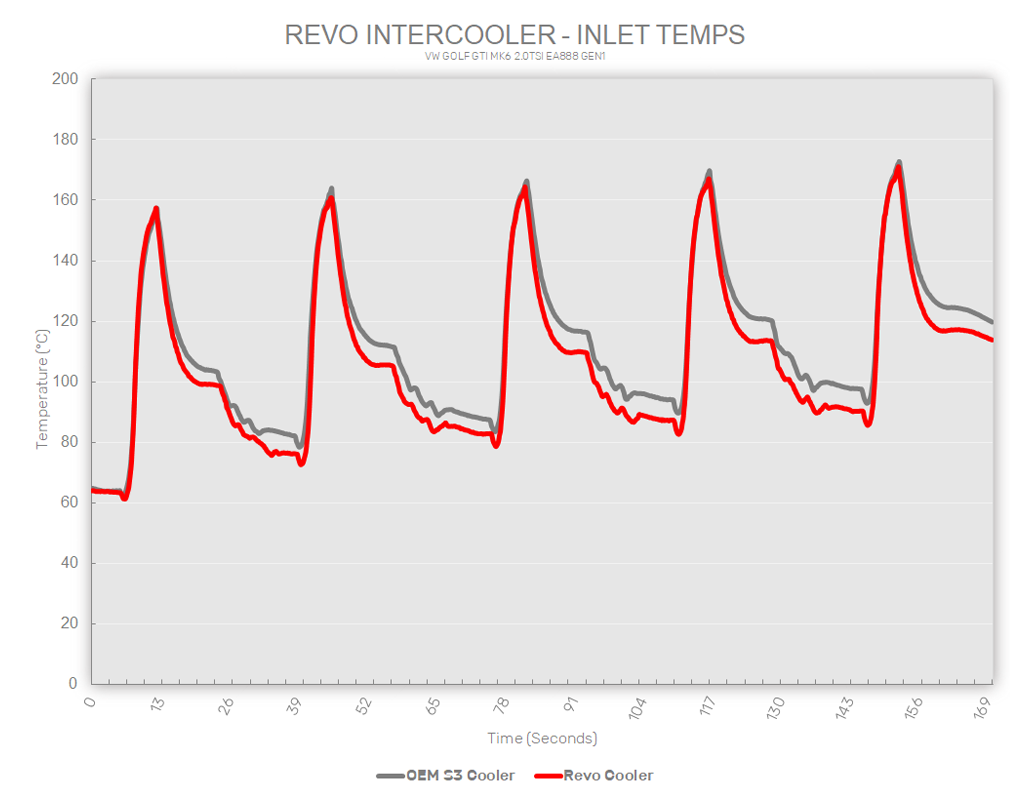

INLET TEMPERATURE

This is a metric used to confirm that testing on the Revo Intercooler. This is used to show that the air temperatures going into the intercooler were similar for each test, confirming that outlet temperatures shown in the following graphs are purely down to differences in intercooler design/construction. As can be seen, the inlet temperatures during testing were equal between both coolers, yet the Revo intercooler produced the lower outlet temps proving the cooling efficiency advantage.

OUTLET TEMPERATURE

This graph illustrates the increased cooling performance of the Revo intercooler vs OEM S3 (8P) aluminium intercooler over all five runs. The Revo Intercooler keeps temperatures well below the OE S3 intercooler throughout all 5 runs.

.png)

Recensioner

Det finns inga recensioner än.